Product Features

How can achieve more water-saving while ensuring cooling efficiency? The concept of dry and wet intermodal cooling is feasible, but there are also many factors to consider. Our company's dry and wet intermodal closed cooling tower adopts a "herringbone" shaped arrangement of finned coils that suck fresh air from the inlet of the pre cooling section of the tower body, thus avoiding serious scaling caused by humid and hot air infiltration into the finned coils. The coil arranged in a "human" shape has a larger heat dissipation area, resulting in greater air cooling value.

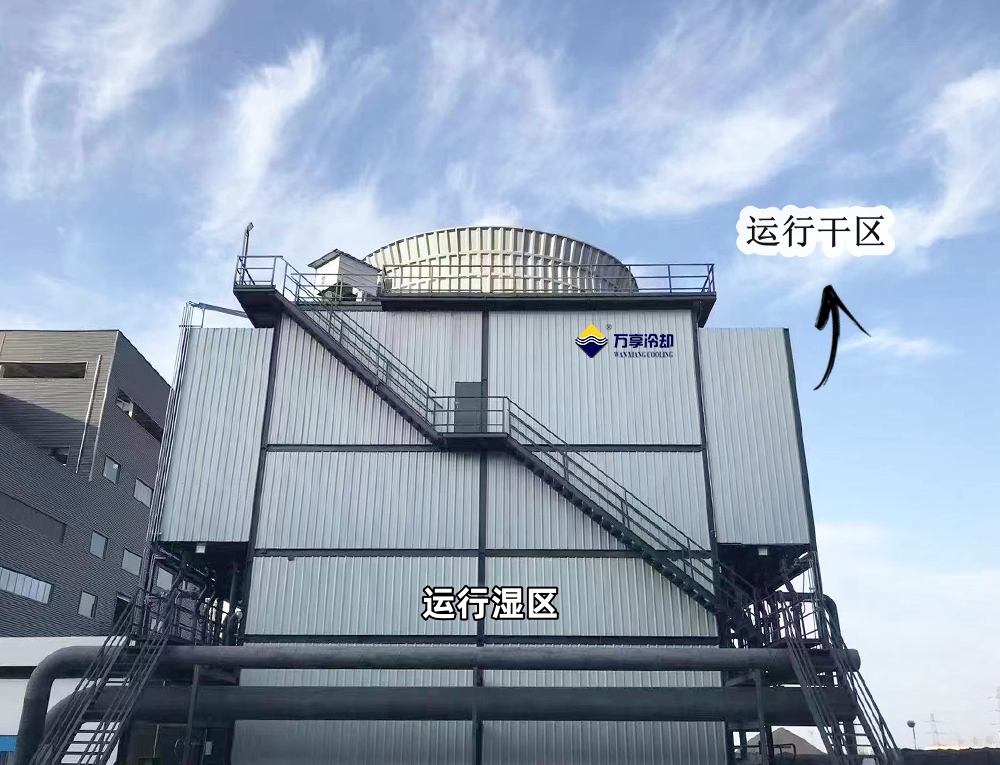

The fluid first enters the finned coil section for cooling, and then enters the main evaporator coil for cooling before flowing out. By adjusting the automatic valve, it is possible to ensure maximum utilization of the dry cooling of the finned tube and minimize the wet cooling of the main evaporator coil. Under low conditions such as reduced load or low ambient temperature, the consumption of evaporative cooling and water is significantly reduced due to the continuous decrease in flow rate through the evaporator coil. The outlet fluid temperature can be reasonably controlled to achieve water-saving effect.

In dry operation mode, the spray water system is turned off, and the fluid to be cooled enters the main evaporator coil from the finned coil. The flow control valve is kept fully open and the fluid is connected in series, thus maximizing the use of the heat exchange surfaces of the dry and wet coils. At the same time, the air inlet angle is adjusted through the air valve to control the air inlet mode. In this operation, there is no water evaporation consumption and no white mist is generated. The product can be selected under conditions between a dry bulb temperature of 5 ℃ -20 ℃ for product selection, and then the appropriate switching point between dry and wet operation can be chosen.