With the implementation of the national technology innovation strategy, the third-generation semiconductor industry and its corresponding electronic information industry are flourishing.

Wanxiang products are widely used in third-generation semiconductor (SiC, GaN) chip manufacturing factories, integrated circuits, chip factories, data centers, and other related fields.

The precise matching system design provides constant temperature and pressure cooling circulating water, and the stable crystallization temperature ensures product yield. The intelligent energy-saving control strategy reduces energy consumption and achieves low PUE operation of data centers. Capable of serving clients including Tianke Heda, Shanghai Institute of Ceramics, Chinese Academy of Sciences, Baoshan Cloud Data Center, etc.

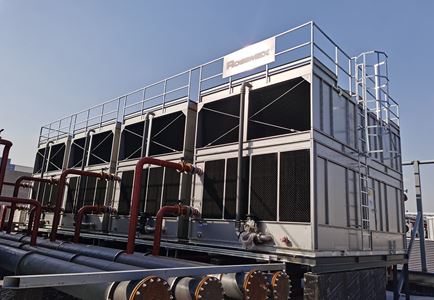

Hebei Tianda Jingyang Semiconductor Technology Co., Ltd.'s annual production of 12000 silicon carbide chips project adopts our company's new dual working condition closed cooling tower with 5 sets to ensure flexible and energy-saving operation in different usage environments.

Tianke HedaHebei Tianda Jingyang Semiconductor Technology Co., Ltd.'s annual production of 12000 silicon carbide chips project adopts our company's new dual working condition closed cooling tower with 5 sets to ensure flexible and energy-saving operation in different usage environments. Tianke HedaHebei Tianda Jingyang Semiconductor Technology Co., Ltd.'s annual production of 12000 silicon carbide chips project adopts our company's new dual working condition closed cooling tower with 5 sets to ensure flexible and energy-saving operation in different usage environments." data-fancybox="fb_142785_1">

Tianke HedaHebei Tianda Jingyang Semiconductor Technology Co., Ltd.'s annual production of 12000 silicon carbide chips project adopts our company's new dual working condition closed cooling tower with 5 sets to ensure flexible and energy-saving operation in different usage environments." data-fancybox="fb_142785_1">

The Shenzhen Heavy Investment Tianke Semiconductor Project is a major provincial project. After full completion, it will produce 6-inch silicon carbide single crystal substrates and silicon carbide epitaxial wafers, providing raw material support for the development of the silicon carbide device industry chain in key areas such as rail transit, new energy, and smart grids, and helping Shenzhen build a national third-generation semiconductor technology innovation highland. This project uses 12 sets of energy-saving and water-saving all steel open cooling towers and secondary energy-efficient closed cooling towers from our company.

Shenzhen Chongtou TiankeThe Shenzhen Heavy Investment Tianke Semiconductor Project is a major provincial project. After full completion, it will produce 6-inch silicon carbide single crystal substrates and silicon carbide epitaxial wafers, providing raw material support for the development of the silicon carbide device industry chain in key areas such as rail transit, new energy, and smart grids, and helping Shenzhen build a national third-generation semiconductor technology innovation highland. This project uses 12 sets of energy-saving and water-saving all steel open cooling towers and secondary energy-efficient closed cooling towers from our company." data-fancybox="fb_142786_2">

Since 2007, Wanxiang has provided EPC cooperation of varying sizes to Shanghai Institute of Ceramics and its cooperative enterprises every year, providing engineering services such as system design, supply of cooling equipment, system construction, operation and maintenance. Over the years, our full cycle products and technical services have received unanimous praise from almost all experts in the research institute.

Shanghai Institute of Ceramics, Chinese Academy of SciencesSince 2007, Wanxiang has provided EPC cooperation of varying sizes to Shanghai Institute of Ceramics and its cooperative enterprises every year, providing engineering services such as system design, supply of cooling equipment, system construction, operation and maintenance. Over the years, our full cycle products and technical services have received unanimous praise from almost all experts in the research institute." data-fancybox="fb_142787_3">

How to solve the high energy consumption of data centers? Industry related enterprises have made various attempts to control the constant temperature and humidity of the computer room environment. The condensing system is also the main source of energy consumption and the key to efficiency conversion. The traditional method uses a shell and tube water-cooled condenser+cooling tower. The Baoshan Cloud project adopts evaporative condensing technology, which can effectively reduce the condensing temperature and evaporate more heat per unit of water consumption. The project adopts our company's specially designed 8 sets of evaporative condensers, which have a positive impact on energy conservation and efficiency improvement.

Kehua Data Co., Ltd. integrates innovative digital technology and provides comprehensive solutions for data centers, high-end power supplies, and clean energy. In small module liquid cooling technology units, the use of closed cooling towers is the most ideal solution. Our company has cooperated with Kehua to make effective attempts in this field, and the Rexroth energy-saving closed cooling tower we provide is very safe and stable.

Giant Rare Earth Permanent Magnet is constructing a 100000 ton/year high-performance sintered neodymium iron boron permanent magnet material project in Mianyang. The project adopts 54 sets of our company's ReShi Mei brand new energy-saving all steel 82/86 series cooling towers, with a total circulating water volume exceeding 25000m 3/h. For the first time, all rare earth permanent magnet motors have been adopted, redefining a new energy-saving driving method for cooling towers. As of the time of writing, it has been safely running for 9 months. In the selection of specific cooling towers for energy-saving projects, considering the purchase cost and energy-saving efficiency, a more complete permanent magnet motor will be the first choice.

Jiangsu Nanda Optoelectronics Co., Ltd. is a leading enterprise in high-purity electronic materials in China. Its manufacturing plant located in Ulanqab adopts four sets of FBNF series dry wet combined operation closed cooling towers from our company, successfully achieving wet operation in summer and dry operation when the temperature is below 6 ℃ in winter, achieving reasonable control of fluid temperature, avoiding icing in winter, and energy-saving and water-saving effects.

Nanda OptoelectronicsJiangsu Nanda Optoelectronics Co., Ltd. is a leading enterprise in high-purity electronic materials in China. Its manufacturing plant located in Ulanqab adopts four sets of FBNF series dry wet combined operation closed cooling towers from our company, successfully achieving wet operation in summer and dry operation when the temperature is below 6 ℃ in winter, achieving reasonable control of fluid temperature, avoiding icing in winter, and energy-saving and water-saving effects." data-fancybox="fb_142793_7">